Industrial Tank Cleaning

Contact usTank Cleaning

Tanks are an intrinsic part of many industrial businesses. When poorly maintained, harmful substances such as acids, alkalines, flammables and toxins can build up. This can make vessels dangerous, compromising their efficiency and affecting product quality. To combat this, regular tank cleaning and maintenance is vital.

What is Tank Cleaning?

Tank cleaning is the essential process of preparing industrial tanks and vessels for inspections, removing blockages and preventing contamination. The best cleaning solution involves ultra high pressure water jets, with Hydroblast providing both man-entry and remote methods to achieve optimal results for your business.

When tank cleaning, you want to make sure that you’re using either a professional company that can provide you with a safe solution or that you’re using quality equipment with the proper training, as improper cleaning can lead to health and safety issues. Hydroblast can provide both of these services, depending on which best suits the needs and budget of your business.

Why is Regular Tank Cleaning Important?

Investing in regular tank cleaning has many benefits. It can prolong the lifespan of the asset and reduce its risk of damage. It is also necessary for inspections, as structural problems can easily be hidden underneath a layer of residue.

At Hydroblast, we often receive calls from companies who have neglected to invest in regular cleaning. In these instances, the industrial tank has become inoperable and costly. We are able to help, deploying our team of expert operatives to clean seemingly impossible blockages. Find out how we cleaned 15 years of residue in our case study, in which our client said that they were “very impressed – we have 3 more tanks to clean when you can come back!”

Our Tank Cleaning Method

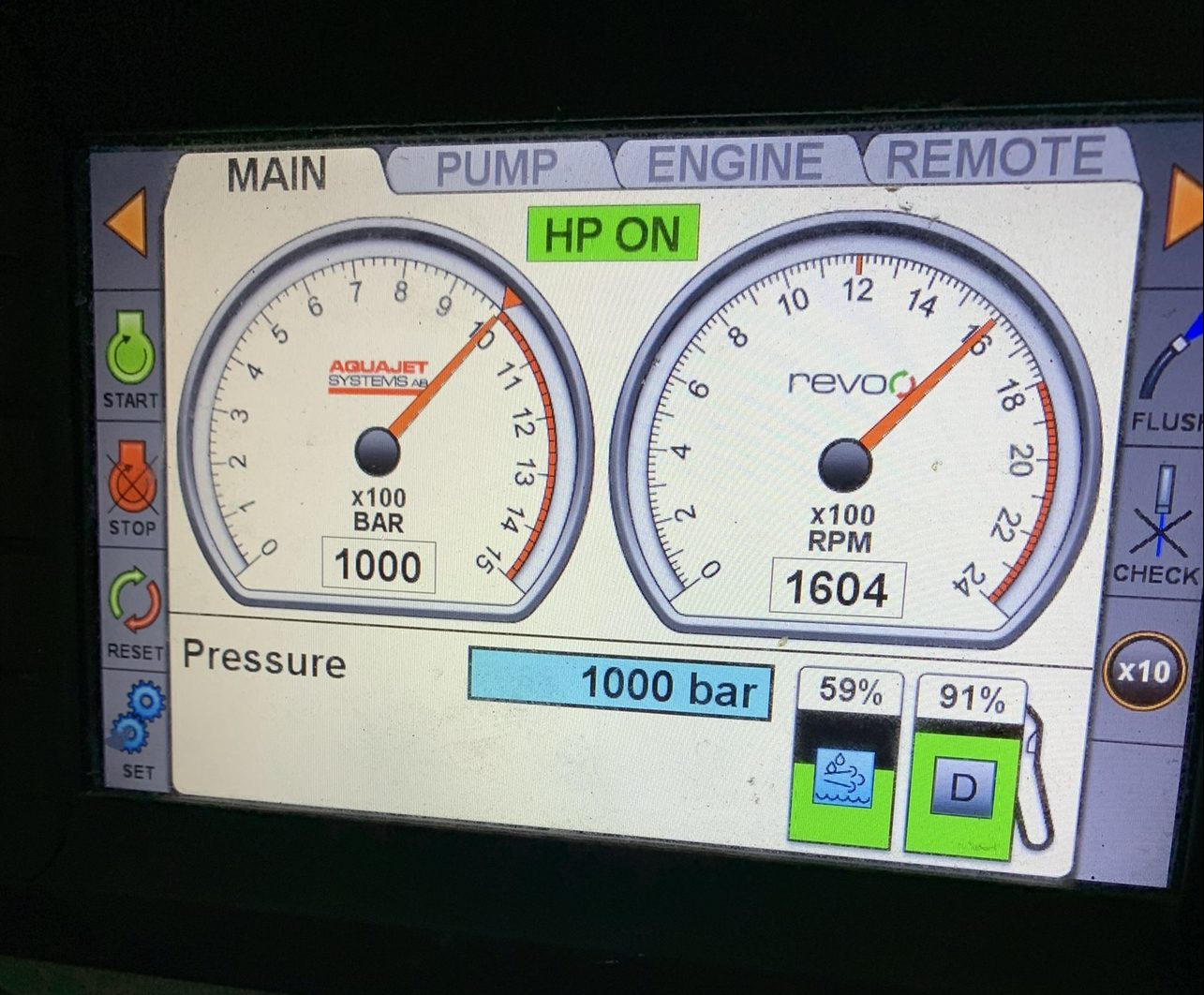

Our method of tank cleaning involves the use of high pressure water jets to remove blockages and residue internally and externally. This form of automated cleaning is safer, faster and more consistent than past methods.

The advanced technology of our jetting robots and lances is used to achieve a thorough clean for a wide range of vessels. Using water is more environmentally-friendly than methods involving solvents, reducing the environmental impact of the process. Hydroblast also has systems in place to treat any harmful waste water, and we hold the ISO 14001 certification for our high environmental management standards.

To achieve optimal results, the water jetting method that we use will depend on the type of tank. When remote access isn’t possible, our staff will physically enter the tank to achieve the desired result. Ultra high pressure hand lancing can be used in these situations, however, it will require highly trained operatives. This is due to the close proximity to the blast zone and the need for specialist equipment, such as RPE and harnesses.

Ideally, industrial tanks should be cleaned remotely with equipment such as the Torus nozzle, which is used by Hydroblast to achieve a thorough and consistent clean for wax, resins, PVA and more. We invest in brand new equipment every year, so we always have the very latest models to hand.

Top-of-the-range technology such as the Torus will hugely reduce the risks for the operative, as they will be kept away from the blast zone and any chemicals from the tank. It will also remove the need for scaffolding, minimising disruption and cost implications for the business.

Difficulties and Dangers

Different types of tank will pose different challenges. Underground petrol storage tanks, for example, may require specialist breathing apparatus, gas detection monitors and submersible pumps to remove waste in addition to lights and fans.

The risks involved will also depend on the structure. Any situation that requires the person to physically enter the tank will pose a significant risk, and it can also be very costly to the business. In these situations, scaffolding will be required to fulfil health and safety requirements, resulting in more downtime for the tank and higher costs for the business.

For an inexperienced operative, the design and structure of a tank can make it incredibly difficult to clean. Its primary purpose is to separate its contents from the outside world, which can make access for maintenance exceptionally difficult. This is why a professional and safety-aware cleaning company such as Hydroblast should be contracted to perform the task.

Water Jetting Training

Many risks associated with industrial tank cleaning can be reduced with the correct planning, safety precautions, and training. Any person involved in cleaning a tank or vessel should be trained in safety awareness and confined space entry. Water jetting injuries can be serious, and there are many hazards associated with man entry tank cleaning in particular.

Specialist Industrial Tank Cleaning Service

At Hydroblast, we have developed an award-winning, safety-first tank cleaning approach that is both fast and effective. We are able to perform one-off and scheduled visits to your company to clean your industrial tanks.

Our focus has always been on the safety of our operatives, alongside delivering consistent results and excellent customer service. We are also ISO 45001 compliant for all of our water jetting activities, and our staff are efficient and experts in their field. This has resulted in many happy clients and lots of repeat business.

To enquire about our tank cleaning services, please contact a member of our expert team today.