Surface Cleaning and Preparation Training

Contact usThe Water Jetting Association (WJA) Approved Surface Cleaning and Preparation Course

Who is the course for?

This course is designed to offer the participant both classroom based theoretical tuition together with practical instruction in the safe and efficient use of high-pressure and ultra-high-water jetting equipment and accessories for various surface cleaning applications.

Are there any prerequisites?

Participants must hold a current valid Safety Awareness Certificate and Photocard issued by the WJA.

What is involved?*

This is a two-part half day course covering surface cleaning and preparation consisting of theoretical classroom based and practical hands on training. At the end of the theoretical element there will be a question paper with 20 questions with a pass mark of 75%.

Once the course has been successfully completed participants will be issued with a Certificate which is issued by the Water Jetting Association (WJA). The Certificate is recognised by the Health and Safety Executive (HSE) and is City and Guild Accredited (C&G). This course does not need to be repeated but please note – If your Safety Awareness certificate goes out of date, for any reason, your other certificates immediately become invalid. A valid Safety Awareness certificate is required to keep all certificates validated.

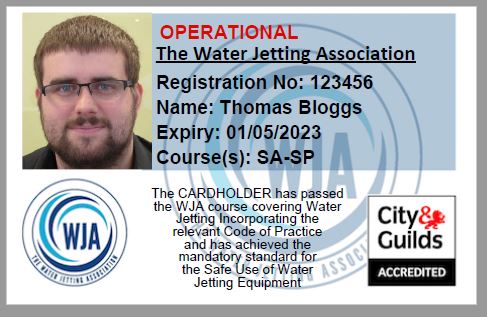

Example of the Surface Cleaning and Preparation Certificate and Photocard issued by the WJA on successful completion of the course. This certificate only has to be taken once and it remains valid as long as a valid Safety Awareness Certificate is in force.

*Surface Cleaning and Preparation Course – Contents

1. Registration and Introduction

2. Review Key Safety Awareness Issues

(included only when presented as a ‘Stand-Alone’ Course)

Nozzles and Jets, Pumps and Ancillaries, Pressure Controls, High Pressure Hose, Hazards and Injuries, Personal Protective Equipment, Operational Procedures.

3. Applications and Machines

Scope of surface cleaning and preparation applications. Range of tasks, and differentiation between surface cleaning & surface preparation. Range of Jetting Machines suitable for surface cleaning/preparation.

4. Jetting Equipment – Nozzles and Ancillaries

Review nozzle principles – fixed jet nozzles, rotating nozzles, life & wear characteristics, associated ancillary equipment including automatic, semi-automatic, and wet abrasive blasting.

5. Jetting Equipment – High Pressure Hose

Hose used in surface cleaning and preparation applications, damage & wear possibilities, hose ancillaries. Review bore size and flow ratings.

6. Jetting Equipment – Machines

Range of jetting machines used, engine controls and instruments. Pump pressure controls, review dump/dry shut and selector/ fail safe types, auto engine speed control systems, pressure safety relief. Water supply/delivery features – filtration requirements, boost feed pumps, built-in anti-freeze provisions.

7. Job Assessment and Planning

Information and assessment – site location, access to work area, surface to be cleaned and layout; base material and contaminants – initial condition and require finished condition; water provision, waste disposal, hazards. Selection of equipment and manning levels – jetting machine/nozzles/accessories, number and duties of operators, single person operation. Determine job method, based on safe system of work.

8. Operational Procedures

Daily checks – manufacturer’s instructions, other items requiring regular checks. Setting-up – permits/authorisations, barriers and warning signs, positioning of machine and equipment, team duties and signals, flushing, leaks check, trial run. Monitoring of operation – flying debris, waste contamination, work standard. Job completion – client inspection, waste removal, equipment decontamination, return site to safe condition.

9. Practical Exercises

Jetting machine and equipment – review features, and demonstrate daily checks, start/run/stop. Job assessment – review and discuss, site location and constraints, accessibility, screening/extraction requirements. Work surface – nature of contamination, work to be carried out and standard of finish. Water supply, effluent drainage. Hazards & use of PPE. Discussion of options and agree job method. Site preparation – setting up work area. Team talk – review job method, signal, set up team(s). Position jetting machine, layout and check equipment. Demonstrate all procedures to full group. For all teams, instruct each operator in each duty. Trainees carry out exercise, each team following instructions to set up, flush, check for leaks, carry out trial run, proceed with operation. Rotate team members through duties. Review at each rotation and final review. Disconnect equipment and clear site.

10. Summary

Review of course content as above, with opportunity for any further discussion before Questionnaire.

Get in Touch…

Contact us today to learn more about our Water Jetting Training Services. You can also book our open courses online, simply select your preferred date on our calendar.